الثلاثاء

تحميص البخار Super heating

Wet steam is steam containing a degree of water, and is one of the main concerns in any steam system. It can reduce plant productivity and product quality, and can cause damage to most items of plant and equipment. Whilst careful drainage and trapping can remove most of the water, it will not deal with the water droplets suspended in the steam. To remove these suspended water droplets, separators are installed in steam pipelines.

The steam produced in a boiler designed to generate saturated steam is inherently wet. Although the dryness fraction will vary according to the type of boiler, most shell type steam boilers will produce steam with a dryness fraction of between 95 and 98%. The water content of the steam produced by the boiler is further increased if priming and carryover occur.

There is always a certain degree of heat loss from the distribution pipe, which causes steam to condense. The condensed water molecules will eventually gravitate towards the bottom of the pipe forming a film of water. Steam flowing over this water can raise ripples that can build up into waves. The tips of the waves tend to break off, throwing droplets of condensate into the steam flow.

The presence of water in steam can cause a number of problems:

The steam produced in a boiler designed to generate saturated steam is inherently wet. Although the dryness fraction will vary according to the type of boiler, most shell type steam boilers will produce steam with a dryness fraction of between 95 and 98%. The water content of the steam produced by the boiler is further increased if priming and carryover occur.

There is always a certain degree of heat loss from the distribution pipe, which causes steam to condense. The condensed water molecules will eventually gravitate towards the bottom of the pipe forming a film of water. Steam flowing over this water can raise ripples that can build up into waves. The tips of the waves tend to break off, throwing droplets of condensate into the steam flow.

The presence of water in steam can cause a number of problems:

- As water is an extremely effective barrier to heat transfer, its presence can reduce plant productivity and product quality. This can be seen in Figure 12.5.1, which shows the temperature profile across a typical heat exchange surface.

Fig. 12.5.1 Temperature profile across a heat exchange surface

- Water droplets travelling at high steam velocities will erode valve seats and fittings, a condition known as wiredrawing. The water droplets will also increase the amount of corrosion.

- Increased scaling of pipework and heating surfaces from the impurities carried in the water droplets.

- Erratic operation of control valves and flowmeters.

- Failure of valves and flowmeters due to rapid wear or waterhammer.

Although there are a number of different designs of separator, they all attempt to remove the moisture that remains suspended in the steam flow, which cannot be removed by drainage and steam trapping. There are three types of separator in common use in steam systems:

- Baffle type - A baffle or vane type separator consists of a number of baffle plates, which cause the flow to change direction a number of times as it passes through the separator body. The suspended water droplets have a greater mass and a greater inertia than the steam; thus, when there is a change in flow direction, the dry steam flows around the baffles and the water droplets collect on the baffles. Furthermore, as the separator has a large cross-sectional area, there is a resulting reduction in the speed of the fluid. This reduces the kinetic energy of the water droplets, and most of them will fall out of suspension. The condensate collects in the bottom of the separator, where it is drained away through a steam trap.

Fig. 12.5.2 A baffle type separator

- Cyclonic type - The cyclonic or centrifugal type separator uses a series of fins to generate high-speed cyclonic flow. The velocity of the steam causes it to swirl around the body of the separator, throwing the heavier, suspended water to the wall, where it drains down to a steam trap installed under the unit.

Fig. 12.5.3 A cyclonic type separator

- Coalescence type - Coalescence type separators provide an obstruction in the steam path. The obstruction is typically a wire mesh pad (sometimes referred to as a demister pad), upon which water molecules become entrapped. These water molecules tend to coalesce, producing droplets that are too large to be carried further by the gas system. As the size of the droplets increases, they become too heavy and ultimately fall into the bottom of the separator.

It is common to find separators, which combine both coalescence and cyclonic type operations. By combining the two methods, the overall efficiency of the separator is improved.

Fig. 12.5.4 A coalescence type separator

Separator efficiency is a measure of the weight of the water separated out in proportion to the total weight of the water carried in by the steam. Outside the laboratory, it is difficult to establish the exact efficiency of a separator, as it depends on the inlet dryness fraction, the fluid velocity and the flow pattern. Erosion of pipe bends, wiredrawing, and waterhammer are, however, indications of the presence of wet steam in steam pipes.

One of the main differences in performance between the baffle type and the cyclonic and coalescence types of separators is that the baffle type is capable of maintaining a high level of efficiency over a wider pipeline velocity range. Cyclone and coalescence type separators typically exhibit efficiencies of 98% at velocities of up to 13 m/s, but this falls off sharply, and at 25 m/s, the efficiency is typically around 50%, according to University research in the UK.

This research has also proven that, for a baffle type separator, the efficiency remains close to 100% over a range of 10 m/s to 30 m/s . The conclusion is that, the baffle type separator is more suited to steam applications, where there is usually some degree of velocity fluctuation. Furthermore, wet steam will be found to run at velocities of over 30 m/s if the pipework is undersized.

One method of overcoming this problem is to use a larger size separator and by increasing the diameter of the pipework immediately upstream of the separator. This will have the effect of reducing the velocity of the steam before it enters the separator.

Example 12.5.1

If a separator with an efficiency of 90% is fitted to a steam main containing steam with a dryness fraction of 0.95, what would the downstream dryness fraction be?

If the initial dryness fraction is 0.95, every kilogram (1000 g) of steam contains:

Since the efficiency of the separator is 90%, only 0.90 x 50 g = 45 g of the water present is removed. This means that the dryness fraction becomes:

In practical terms, the steam can be considered completely dry.

If however, the separator efficiency is only 50%, only 25 g of the water will be removed. This results in a dryness fraction of:

Although an improvement on the original dryness of 0.95, the steam will still contain a significant amount of water.

The pressure drop across a baffle type separator is very low due to the reduction in the velocity of the steam, which is created by the large increase in cross-sectional area provided by the separator body. The pressure drop is typically less than the equivalent length of the same nominal diameter pipe. In comparison, the pressure drop across a cyclonic type separator is somewhat higher, as the velocity of the fluid has to be maintained to generate the cyclone effect.

On non-critical applications, baffle type separators are typically sized according to the pipeline size; it is necessary however to check that the chosen size ensures maximum separation efficiency, and that the pressure drop is within acceptable limits. On critical applications, it is more common to select the separator based on operating pressure and flowrate, so as to give a suitable efficiency and pressure drop. Sizing a cyclonic type separator is more complicated, as it is important to ensure that the velocity through the separator is suitable to maintain a high level of efficiency and that the pressure drop across the separator is acceptable.

Example 12.5.2 outlines the selection of a baffle type separator from a typical manufacture's specification chart.

Example 12.5.2

Using the sizing chart in Figure 12.5.5, select a suitably sized separator for a pressure reducing station, with an upstream pressure of 12 bar g and passing 500 kg/h of steam through a 32 mm pipeline, If the flowrate were doubled to 1000 kg/h, what size should the separator be?

1. Plot point A where the steam pressure and the flowrate cross and draw a horizontal line across from this point. Any separator curve that is bisected by this line within the shaded area will operate at near 100% efficiency.

2. Select the line size separator, i.e. 32 mm at point B.

3. The line velocity for any size can be determined by dropping a vertical line from this intersection. From point B, this line crosses the velocity axis at 18 m/s.

4. To determine the pressure drop across the separator, where the vertical line, extended from point B, crosses the line C-C, plot a horizontal line. Then drop a vertical line from point A. The point of intersection, D, is the pressure drop across the separator.

5. Repeating this procedure for a 1000 kg/h flowrate, generates points X, Y and Z. It can be seen that point Y falls outside the shaded region and the separator will not operate at maximum efficiency. Here, it would be advisable to use a larger size separator; a DN40 separator would be selected, as depicted by point Z, along with a pressure drop of about 0.07 bar at point W.

Fig. 12.5.5 Manufacturer's sizing chart for a baffle type separator

Table 12.5.1 summarises the important differences in the performance of baffle and cyclone type separators.

A suitable steam trap should be fitted to the condensate outlet of the separator to ensure the efficient removal of condensate, without the loss of live steam. The most suitable type of steam trap is the ball float type, which ensures immediate condensate removal. Some separators include the steam trap mechanism inside the separator body.

Most vertical separators have a tapping on the top of the body. This can be used for an air vent, facilitating the removal of air from the steam space during start-up.

Insulation

If a separator is left uninsulated, it can actually induce water droplets to form rather than eliminating them, because of the large surface area exposed to the environment. Furthermore, significant amounts of heat energy can be lost from the surface of the separator. For example, insulating a separator containing steam at 150°C and exposed to ambient temperatures of 15°C, will produce an annual energy saving of 8600 MJ (Based on heat loss due to radiation only, assuming still air conditions and 8760 hours of operation per year). By fitting an insulation jacket, this heat loss can be drastically reduced and the energy savings justify the initial cost of the insulation, within an extremely short time.

Insulation jackets designed to fit over a particular separator should be used, as the shape of the separator, particularly if it is flanged, makes it difficult to insulate. Standard flange covers leave the body exposed, and therefore have a limited effect in the reduction of heat loss.

Even with the best insulation, it is not possible to eliminate all the heat loss from a product. The efficiency of separator insulation is typically above 90%. It is important to use a jacket that is designed for a particular separator; otherwise, the insulation efficiency will decrease. Properly insulated separators also reduce the risk of personal injury from burns

توزيعة البخار

The steam distribution system is the essential link between the steam generator and the steam user.

This Tutorial will look at methods of carrying steam from a central source to the point of use. The central source might be a boiler house or the discharge from a co-generation plant. The boilers may burn primary fuel, or be waste heat boilers using exhaust gases from high temperature processes, engines or even incinerators. Whatever the source, an efficient steam distribution system is essential if steam of the right quality and pressure is to be supplied, in the right quantity, to the steam using equipment. Installation and maintenance of the steam system are important issues, and must be considered at the design stage.

Steam system basicsThis Tutorial will look at methods of carrying steam from a central source to the point of use. The central source might be a boiler house or the discharge from a co-generation plant. The boilers may burn primary fuel, or be waste heat boilers using exhaust gases from high temperature processes, engines or even incinerators. Whatever the source, an efficient steam distribution system is essential if steam of the right quality and pressure is to be supplied, in the right quantity, to the steam using equipment. Installation and maintenance of the steam system are important issues, and must be considered at the design stage.

From the outset, an understanding of the basic steam circuit, or 'steam and condensate loop' is required - see Figure 10.1.1. As steam condenses in a process, flow is induced in the supply pipe. Condensate has a very small volume compared to the steam, and this causes a pressure drop, which causes the steam to flow through the pipes.

Fig. 10.1.1 A typical basic steam circuit

The steam generated in the boiler must be conveyed through pipework to the point where its heat energy is required. Initially there will be one or more main pipes, or 'steam mains', which carry steam from the boiler in the general direction of the steam using plant. Smaller branch pipes can then carry the steam to the individual pieces of equipment.

When the boiler main isolating valve (commonly called the 'crown' valve) is opened, steam immediately passes from the boiler into and along the steam mains to the points at lower pressure. The pipework is initially cooler than the steam, so heat is transferred from the steam to the pipe. The air surrounding the pipes is also cooler than the steam, so the pipework will begin to transfer heat to the air.

Steam on contact with the cooler pipes will begin to condense immediately. On start-up of the system, the condensing rate will be at its maximum, as this is the time where there is maximum temperature difference between the steam and the pipework. This condensing rate is commonly called the 'starting load'. Once the pipework has warmed up, the temperature difference between the steam and pipework is minimal, but some condensation will occur as the pipework still continues to transfer heat to the surrounding air. This condensing rate is commonly called the 'running load'.

The resulting condensation (condensate) falls to the bottom of the pipe and is carried along by the steam flow and assisted by gravity, due to the gradient in the steam main that should be arranged to fall in the direction of steam flow. The condensate will then have to be drained from various strategic points in the steam main.

When the valve on the steam pipe serving an item of steam using plant is opened, steam flowing from the distribution system enters the plant and again comes into contact with cooler surfaces. The steam then transfers its energy in warming up the equipment and product (starting load), and, when up to temperature, continues to transfer heat to the process (running load).

There is now a continuous supply of steam from the boiler to satisfy the connected load and to maintain this supply more steam must be generated. In order to do this, more water (and fuel to heat this water) is supplied to the boiler to make up for that water which has previously been evaporated into steam.

The condensate formed in both the steam distribution pipework and in the process equipment is a convenient supply of useable hot boiler feedwater. Although it is important to remove this condensate from the steam space, it is a valuable commodity and should not be allowed to run to waste. Returning all condensate to the boiler feedtank closes the basic steam loop, and should be practised wherever practical. The return of condensate to the boiler is discussed further in Block 13, 'Condensate Removal', and Block 14,'Condensate Management'.

The working pressure

The distribution pressure of steam is influenced by a number of factors, but is limited by:

Fig. 10.1.1 A typical basic steam circuit

The steam generated in the boiler must be conveyed through pipework to the point where its heat energy is required. Initially there will be one or more main pipes, or 'steam mains', which carry steam from the boiler in the general direction of the steam using plant. Smaller branch pipes can then carry the steam to the individual pieces of equipment.

When the boiler main isolating valve (commonly called the 'crown' valve) is opened, steam immediately passes from the boiler into and along the steam mains to the points at lower pressure. The pipework is initially cooler than the steam, so heat is transferred from the steam to the pipe. The air surrounding the pipes is also cooler than the steam, so the pipework will begin to transfer heat to the air.

Steam on contact with the cooler pipes will begin to condense immediately. On start-up of the system, the condensing rate will be at its maximum, as this is the time where there is maximum temperature difference between the steam and the pipework. This condensing rate is commonly called the 'starting load'. Once the pipework has warmed up, the temperature difference between the steam and pipework is minimal, but some condensation will occur as the pipework still continues to transfer heat to the surrounding air. This condensing rate is commonly called the 'running load'.

The resulting condensation (condensate) falls to the bottom of the pipe and is carried along by the steam flow and assisted by gravity, due to the gradient in the steam main that should be arranged to fall in the direction of steam flow. The condensate will then have to be drained from various strategic points in the steam main.

When the valve on the steam pipe serving an item of steam using plant is opened, steam flowing from the distribution system enters the plant and again comes into contact with cooler surfaces. The steam then transfers its energy in warming up the equipment and product (starting load), and, when up to temperature, continues to transfer heat to the process (running load).

There is now a continuous supply of steam from the boiler to satisfy the connected load and to maintain this supply more steam must be generated. In order to do this, more water (and fuel to heat this water) is supplied to the boiler to make up for that water which has previously been evaporated into steam.

The condensate formed in both the steam distribution pipework and in the process equipment is a convenient supply of useable hot boiler feedwater. Although it is important to remove this condensate from the steam space, it is a valuable commodity and should not be allowed to run to waste. Returning all condensate to the boiler feedtank closes the basic steam loop, and should be practised wherever practical. The return of condensate to the boiler is discussed further in Block 13, 'Condensate Removal', and Block 14,'Condensate Management'.

The working pressure

The distribution pressure of steam is influenced by a number of factors, but is limited by:

- The maximum safe working pressure of the boiler.

- The minimum pressure required at the plant.

As steam passes through the distribution pipework, it will inevitably lose pressure due to:

- Frictional resistance within the pipework (detailed in Tutorial 10.2).

- Condensation within the pipework as heat is transferred to the environment.

Therefore allowance should be made for this pressure loss when deciding upon the initial distribution pressure.

A kilogram of steam at a higher pressure occupies less volume than at a lower pressure. It follows that, if steam is generated in the boiler at a high pressure and also distributed at a high pressure, the size of the distribution mains will be smaller than that for a low-pressure system for the same heat load. Figure 10.1.2 illustrates this point.

Fig. 10.1.2 Dry saturated steam - pressure/specific volume relationship

Generating and distributing steam at higher pressure offers three important advantages:

A kilogram of steam at a higher pressure occupies less volume than at a lower pressure. It follows that, if steam is generated in the boiler at a high pressure and also distributed at a high pressure, the size of the distribution mains will be smaller than that for a low-pressure system for the same heat load. Figure 10.1.2 illustrates this point.

Fig. 10.1.2 Dry saturated steam - pressure/specific volume relationship

Generating and distributing steam at higher pressure offers three important advantages:

- The thermal storage capacity of the boiler is increased, helping it to cope more efficiently with fluctuating loads, minimising the risk of producing wet and dirty steam.

- Smaller bore steam mains are required, resulting in lower capital cost, for materials such as pipes, flanges, supports, insulation and labour.

- Smaller bore steam mains cost less to insulate.

Having distributed at a high pressure, it will be necessary to reduce the steam pressure to each zone or point of use in the system in order to correspond with the maximum pressure required by the application. Local pressure reduction to suit individual plant will also result in drier steam at the point of use. (Tutorial 2.3 provides an explanation of this).

Note: It is sometimes thought that running a steam boiler at a lower pressure than its rated pressure will save fuel. This logic is based on more fuel being needed to raise steam to a higher pressure.

Whilst there is an element of truth in this logic, it should be remembered that it is the connected load, and not the boiler output, which determines the rate at which energy is used. The same amount of energy is used by the load whether the boiler raises steam at 4 bar g, 10 bar g or 100 bar g. Standing losses, flue losses, and running losses are increased by operating at higher pressures, but these losses are reduced by insulation and proper condensate return systems. These losses are marginal when compared to the benefits of distributing steam at high pressure.

Pressure reduction

The common method for reducing pressure at the point where steam is to be used is to use a pressure reducing valve, similar to the one shown in the pressure reducing station Figure 10.1.3.

Fig. 10.1.3 Typical pressure reducing valve station

A separator is installed upstream of the reducing valve to remove entrained water from incoming wet steam, thereby ensuring high quality steam to pass through the reducing valve. This is discussed in more detail in Tutorial 9.3 and Tutorial 12.5.

Plant downstream of the pressure reducing valve is protected by a safety valve. If the pressure reducing valve fails, the downstream pressure may rise above the maximum allowable working pressure of the steam using equipment. This, in turn, may permanently damage the equipment, and, more importantly, constitute a danger to personnel.

With a safety valve fitted, any excess pressure is vented through the valve, and will prevent this from happening (safety valves are discussed in Block 9).

Other components included in the pressure reducing valve station are:

Note: It is sometimes thought that running a steam boiler at a lower pressure than its rated pressure will save fuel. This logic is based on more fuel being needed to raise steam to a higher pressure.

Whilst there is an element of truth in this logic, it should be remembered that it is the connected load, and not the boiler output, which determines the rate at which energy is used. The same amount of energy is used by the load whether the boiler raises steam at 4 bar g, 10 bar g or 100 bar g. Standing losses, flue losses, and running losses are increased by operating at higher pressures, but these losses are reduced by insulation and proper condensate return systems. These losses are marginal when compared to the benefits of distributing steam at high pressure.

Pressure reduction

The common method for reducing pressure at the point where steam is to be used is to use a pressure reducing valve, similar to the one shown in the pressure reducing station Figure 10.1.3.

Fig. 10.1.3 Typical pressure reducing valve station

A separator is installed upstream of the reducing valve to remove entrained water from incoming wet steam, thereby ensuring high quality steam to pass through the reducing valve. This is discussed in more detail in Tutorial 9.3 and Tutorial 12.5.

Plant downstream of the pressure reducing valve is protected by a safety valve. If the pressure reducing valve fails, the downstream pressure may rise above the maximum allowable working pressure of the steam using equipment. This, in turn, may permanently damage the equipment, and, more importantly, constitute a danger to personnel.

With a safety valve fitted, any excess pressure is vented through the valve, and will prevent this from happening (safety valves are discussed in Block 9).

Other components included in the pressure reducing valve station are:

- The primary isolating valve - To shut the system down for maintenance.

- The primary pressure gauge - To monitor the integrity of supply.

- The strainer - To keep the system clean.

- The secondary pressure gauge - To set and monitor the downstream pressure.

- The secondary isolating valve - To assist in setting the downstream pressure on no-load conditions.

الموصفات التى يجب توافرها فى انابيب البخار

Standards and wall thickness

There are a number of piping standards in existence around the world, but arguably the most global are those derived by the American Petroleum Institute (API), where pipes are categorised in schedule numbers.

These schedule numbers bear a relation to the pressure rating of the piping. There are eleven Schedules ranging from the lowest at 5 through 10, 20, 30, 40, 60, 80, 100, 120, 140 to schedule No. 160. For nominal size piping 150 mm and smaller, Schedule 40 (sometimes called 'standard weight') is the lightest that would be specified for steam applications.

Regardless of schedule number, pipes of a particular size all have the same outside diameter (not withstanding manufacturing tolerances). As the schedule number increases, the wall thickness increases, and the actual bore is reduced. For example:

There are a number of piping standards in existence around the world, but arguably the most global are those derived by the American Petroleum Institute (API), where pipes are categorised in schedule numbers.

These schedule numbers bear a relation to the pressure rating of the piping. There are eleven Schedules ranging from the lowest at 5 through 10, 20, 30, 40, 60, 80, 100, 120, 140 to schedule No. 160. For nominal size piping 150 mm and smaller, Schedule 40 (sometimes called 'standard weight') is the lightest that would be specified for steam applications.

Regardless of schedule number, pipes of a particular size all have the same outside diameter (not withstanding manufacturing tolerances). As the schedule number increases, the wall thickness increases, and the actual bore is reduced. For example:

- A 100 mm Schedule 40 pipe has an outside diameter of 114.30 mm, a wall thickness of 6.02 mm, giving a bore of 102.26 mm.

- A 100 mm Schedule 80 pipe has an outside diameter of 114.30 mm, a wall thickness of 8.56 mm, giving a bore of 97.18 mm.

Only Schedules 40 and 80 cover the full range from 15 mm up to 600 mm nominal sizes and are the most commonly used schedule for steam pipe installations.

This Tutorial considers Schedule 40 pipework as covered in BS 1600.

Tables of schedule numbers can be obtained from BS 1600 which are used as a reference for the nominal pipe size and wall thickness in millimetres. Table 10.2.1 compares the actual bore sizes of different sized pipes, for different schedule numbers.

In mainland Europe, pipe is manufactured to DIN standards, and DIN 2448 pipe is included in Table 10.2.1.

Table 10.2.1 Comparison of pipe standards and actual bore diameters.

In the United Kingdom, piping to EN 10255, (steel tubes and tubulars suitable for screwing to BS 21 threads) is also used in applications where the pipe is screwed rather than flanged. They are commonly referred to as 'Blue Band' and 'Red Band'; this being due to their banded identification marks. The different colours refer to particular grades of pipe:

This Tutorial considers Schedule 40 pipework as covered in BS 1600.

Tables of schedule numbers can be obtained from BS 1600 which are used as a reference for the nominal pipe size and wall thickness in millimetres. Table 10.2.1 compares the actual bore sizes of different sized pipes, for different schedule numbers.

In mainland Europe, pipe is manufactured to DIN standards, and DIN 2448 pipe is included in Table 10.2.1.

Table 10.2.1 Comparison of pipe standards and actual bore diameters.

In the United Kingdom, piping to EN 10255, (steel tubes and tubulars suitable for screwing to BS 21 threads) is also used in applications where the pipe is screwed rather than flanged. They are commonly referred to as 'Blue Band' and 'Red Band'; this being due to their banded identification marks. The different colours refer to particular grades of pipe:

- Red Band, being heavy grade, is commonly used for steam pipe applications.

- Blue Band, being medium grade, is commonly used for air distribution systems, although it is sometimes used for low-pressure steam systems.

The coloured bands are 50 mm wide, and their positions on the pipe denote its length. Pipes less than 4 metres in length only have a coloured band at one end, while pipes of 4 to 7 metres in length have a coloured band at either end.

Fig. 10.2.1 Red band, branded pipe, - heavy grade

Fig. 10.2.2 Blue band, branded pipe, - medium grade, between 4-7 metres in length

Pipe material

Fig. 10.2.1 Red band, branded pipe, - heavy grade

Fig. 10.2.2 Blue band, branded pipe, - medium grade, between 4-7 metres in length

Pipes for steam systems are commonly manufactured from carbon steel to ANSI B 16.9 A106. The same material may be used for condensate lines, although copper tubing is preferred in some industries.

For high temperature superheated steam mains, additional alloying elements, such as chromium and molybdenum, are included to improve tensile strength and creep resistance at high temperatures.

Typically, pipes are supplied in 6 metre lengths.

For high temperature superheated steam mains, additional alloying elements, such as chromium and molybdenum, are included to improve tensile strength and creep resistance at high temperatures.

Typically, pipes are supplied in 6 metre lengths.

Pipeline sizing

The objective of the steam distribution system is to supply steam at the correct pressure to the point of use. It follows, therefore, that pressure drop through the distribution system is an important feature.

Liquids

Bernoulli's Theorem (Daniel Bernoulli 1700 - 1782) is discussed in Block 4 - Flowmetering. D'Arcy (D'Arcy Thompson 1860 - 1948) added that for fluid flow to occur, there must be more energy at Point 1 than Point 2 (see Figure 10.2.3). The difference in energy is used to overcome frictional resistance between the pipe and the flowing fluid.

Fig. 10.2.3 Friction in pipes

Bernoulli relates changes in the total energy of a flowing fluid to energy dissipation expressed either in terms of a head loss hf (m) or specific energy loss g hf (J/kg). This, in itself, is not very useful without being able to predict the pressure losses that will occur in particular circumstances.

Here, one of the most important mechanisms of energy dissipation within a flowing fluid is introduced, that is, the loss in total mechanical energy due to friction at the wall of a uniform pipe carrying a steady flow of fluid.

The loss in the total energy of fluid flowing through a circular pipe must depend on:

L=The length of the pipe (m)D=The pipe diameter (m)u=The mean velocity of the fluid flow (m/s)m=The dynamic viscosity of the fluid (kg/m s=Pa s)ρ=The fluid density (kg/m3)ks=The roughness of the pipe wall* (m)

*Since the energy dissipation is associated with shear stress at the pipe wall, the nature of the wall surface will be influential, as a smooth surface will interact with the fluid in a different way than a rough surface.

All these variables are brought together in the D'Arcy-Weisbach equation (often referred to as the D'Arcy equation), and shown as Equation 10.2.1. This equation also introduces a dimensionless term referred to as the friction factor, which relates the absolute pipe roughness to the density, velocity and viscosity of the fluid and the pipe diameter.

The term that relates fluid density, velocity and viscosity and the pipe diameter is called the Reynolds number, named after Osborne Reynolds (1842-1912, of Owens College, Manchester, United Kingdom), who pioneered this technical approach to energy losses in flowing fluids circa 1883.

The D'Arcy equation (Equation 10.2.1):

Equation 10.2.1

Where:

hf=Head loss to friction (m)f=Friction factor (dimensionless)L=Lengthu=Flow velocity (m/s)g=Gravitational constant (9.81 m/s2)D=Pipe diameter (m)

Interesting point

Readers in some parts of the world may recognise the D'Arcy equation in a slightly different form, as shown in Equation 10.2.2. Equation 10.2.2 is similar to Equation 10.2.1 but does not contain the constant 4.

Equation 10.2.2

The reason for the difference is the type of friction factor used. It is essential that the right version of the D'Arcy equation be used with the selected friction factor. Matching the wrong equation to the wrong friction factor will result in a 400% error and it is therefore important that the correct combination of equation and friction factor is utilised. Many textbooks simply do not indicate which friction factors are defined, and a judgement must sometimes be based on the magnitudes quoted.

Equation 10.2.2 tends to be used by those who traditionally work in Imperial units, and still tends to be used by practitioners in the United States and Pacific rim regions even when metric pipe sizes are quoted. Equation 10.2.1 tends to be used by those who traditionally work in SI units and tends more to be used by European practitioners. For the same Reynolds number and relative roughness, the 'Imperial based friction factor' will be exactly four times larger than the 'SI based friction factor'.

Friction factors can be determined either from a Moody chart or, for turbulent flows, can be calculated from Equation 10.2.3, a development of the Colebrook - White formula.

Equation 10.2.3

Where:

f=Friction factor (Relates to the SI Moody chart)ks=Absolute pipe roughness (m)D=

Pipe bore (m)Re=Reynolds number (dimensionless)

However, Equation 10.2.3 is difficult to use because the friction factor appears on both sides of the equation, and it is for this reason that manual calculations are likely to be carried out by using the Moody chart.

On an SI style Moody chart, the friction factor scale might typically range from 0.002 to 0.02, whereas on an Imperial style Moody chart, this scale might range from 0.008 to 0.08.

As a general rule, for turbulent flow with Reynolds numbers between 4000 and 100000, 'SI based' friction factors will be of the order suggested by Equation 10.2.4, whilst 'Imperial based' friction factors will be of the order suggested by Equation 10.2.5.

Equation 10.2.4 - 'SI based' friction factors

Equation 10.2.4 - 'SI based' friction factors

Equation 10.2.5 - 'Imperial based' friction factors

Equation 10.2.5 - 'Imperial based' friction factors

The friction factor used will determine whether the D'Arcy Equation 10.2.1 or 10.2.2 is used.

For 'SI based' friction factors, use Equation 10.2.1; for 'Imperial based' friction factors, use

Equation 10.2.2.

Example 10.2.1 - Water pipe

Determine the velocity, friction factor and the difference in pressure between two points

1 km apart in a 150 mm constant bore horizontal pipework system if the water flowrate is

45 m3/h at 15°C.

In essence, the friction factor depends on the Reynolds number (Re) of the flowing liquid and the relative roughness (kS/d) of the inside of the pipe; the former calculated from Equation 10.2.6, and the latter from Equation 10.2.7.

Reynolds number (Re)

Equation 10.2.6

Where:

Re=Reynolds numberρ=Density of water=1000 kg/m3u=Velocity of water=0.71 m/sD=Pipe diameter=0.15 mm=Dynamic viscosity of water (at 15°C)=1.138 x 10-3 kg/m s (from steam tables)

From Equation 10.2.6:

The pipe roughness or 'ks' value (often quoted as 'e' in some texts) is taken from standard tables, and for 'commercial steel pipe' would generally be taken as 0.000045 metres.

From this the relative roughness is determined (as this is what the Moody chart requires).

Equation 10.2.7

From Equation 10.2.7:

The friction factor can now be determined from the Moody chart and the friction head loss calculated from the relevant D'Arcy Equation.

From the European Moody chart (Figure 10.2.4),

Where: ks/D = 0.0003 Re = 93585: Friction factor (f) = 0.005

Fig. 10.2.4 'SI based' Moody chart (abridged)

From the European D'Arcy equation (Equation 10.2.1):

From the USA / AUS Moody chart (Figure 10.2.5),

Where: ks/D = 0.0003 Re = 93 585 Friction factor (f) = 0.02

Fig. 10.2.5 'Imperial based' Moody chart (abridged)

From the USA / AUS D'Arcy equation (Equation 10.2.2):

The same friction head loss is obtained by using the different friction factors and relevant D'Arcy equations.

In practice whether for water pipes or steam pipes, a balance is drawn between pipe size and pressure loss.

SteamLiquids

Bernoulli's Theorem (Daniel Bernoulli 1700 - 1782) is discussed in Block 4 - Flowmetering. D'Arcy (D'Arcy Thompson 1860 - 1948) added that for fluid flow to occur, there must be more energy at Point 1 than Point 2 (see Figure 10.2.3). The difference in energy is used to overcome frictional resistance between the pipe and the flowing fluid.

Fig. 10.2.3 Friction in pipes

Bernoulli relates changes in the total energy of a flowing fluid to energy dissipation expressed either in terms of a head loss hf (m) or specific energy loss g hf (J/kg). This, in itself, is not very useful without being able to predict the pressure losses that will occur in particular circumstances.

Here, one of the most important mechanisms of energy dissipation within a flowing fluid is introduced, that is, the loss in total mechanical energy due to friction at the wall of a uniform pipe carrying a steady flow of fluid.

The loss in the total energy of fluid flowing through a circular pipe must depend on:

L=The length of the pipe (m)D=The pipe diameter (m)u=The mean velocity of the fluid flow (m/s)m=The dynamic viscosity of the fluid (kg/m s=Pa s)ρ=The fluid density (kg/m3)ks=The roughness of the pipe wall* (m)

*Since the energy dissipation is associated with shear stress at the pipe wall, the nature of the wall surface will be influential, as a smooth surface will interact with the fluid in a different way than a rough surface.

All these variables are brought together in the D'Arcy-Weisbach equation (often referred to as the D'Arcy equation), and shown as Equation 10.2.1. This equation also introduces a dimensionless term referred to as the friction factor, which relates the absolute pipe roughness to the density, velocity and viscosity of the fluid and the pipe diameter.

The term that relates fluid density, velocity and viscosity and the pipe diameter is called the Reynolds number, named after Osborne Reynolds (1842-1912, of Owens College, Manchester, United Kingdom), who pioneered this technical approach to energy losses in flowing fluids circa 1883.

The D'Arcy equation (Equation 10.2.1):

Equation 10.2.1

Where:

hf=Head loss to friction (m)f=Friction factor (dimensionless)L=Lengthu=Flow velocity (m/s)g=Gravitational constant (9.81 m/s2)D=Pipe diameter (m)

Interesting point

Readers in some parts of the world may recognise the D'Arcy equation in a slightly different form, as shown in Equation 10.2.2. Equation 10.2.2 is similar to Equation 10.2.1 but does not contain the constant 4.

Equation 10.2.2

The reason for the difference is the type of friction factor used. It is essential that the right version of the D'Arcy equation be used with the selected friction factor. Matching the wrong equation to the wrong friction factor will result in a 400% error and it is therefore important that the correct combination of equation and friction factor is utilised. Many textbooks simply do not indicate which friction factors are defined, and a judgement must sometimes be based on the magnitudes quoted.

Equation 10.2.2 tends to be used by those who traditionally work in Imperial units, and still tends to be used by practitioners in the United States and Pacific rim regions even when metric pipe sizes are quoted. Equation 10.2.1 tends to be used by those who traditionally work in SI units and tends more to be used by European practitioners. For the same Reynolds number and relative roughness, the 'Imperial based friction factor' will be exactly four times larger than the 'SI based friction factor'.

Friction factors can be determined either from a Moody chart or, for turbulent flows, can be calculated from Equation 10.2.3, a development of the Colebrook - White formula.

Equation 10.2.3

Where:

f=Friction factor (Relates to the SI Moody chart)ks=Absolute pipe roughness (m)D=

Pipe bore (m)Re=Reynolds number (dimensionless)

However, Equation 10.2.3 is difficult to use because the friction factor appears on both sides of the equation, and it is for this reason that manual calculations are likely to be carried out by using the Moody chart.

On an SI style Moody chart, the friction factor scale might typically range from 0.002 to 0.02, whereas on an Imperial style Moody chart, this scale might range from 0.008 to 0.08.

As a general rule, for turbulent flow with Reynolds numbers between 4000 and 100000, 'SI based' friction factors will be of the order suggested by Equation 10.2.4, whilst 'Imperial based' friction factors will be of the order suggested by Equation 10.2.5.

Equation 10.2.4 - 'SI based' friction factors

Equation 10.2.4 - 'SI based' friction factors Equation 10.2.5 - 'Imperial based' friction factors

Equation 10.2.5 - 'Imperial based' friction factorsThe friction factor used will determine whether the D'Arcy Equation 10.2.1 or 10.2.2 is used.

For 'SI based' friction factors, use Equation 10.2.1; for 'Imperial based' friction factors, use

Equation 10.2.2.

Example 10.2.1 - Water pipe

Determine the velocity, friction factor and the difference in pressure between two points

1 km apart in a 150 mm constant bore horizontal pipework system if the water flowrate is

45 m3/h at 15°C.

In essence, the friction factor depends on the Reynolds number (Re) of the flowing liquid and the relative roughness (kS/d) of the inside of the pipe; the former calculated from Equation 10.2.6, and the latter from Equation 10.2.7.

Reynolds number (Re)

Equation 10.2.6

Where:

Re=Reynolds numberρ=Density of water=1000 kg/m3u=Velocity of water=0.71 m/sD=Pipe diameter=0.15 mm=Dynamic viscosity of water (at 15°C)=1.138 x 10-3 kg/m s (from steam tables)

From Equation 10.2.6:

The pipe roughness or 'ks' value (often quoted as 'e' in some texts) is taken from standard tables, and for 'commercial steel pipe' would generally be taken as 0.000045 metres.

From this the relative roughness is determined (as this is what the Moody chart requires).

Equation 10.2.7

From Equation 10.2.7:

The friction factor can now be determined from the Moody chart and the friction head loss calculated from the relevant D'Arcy Equation.

From the European Moody chart (Figure 10.2.4),

Where: ks/D = 0.0003 Re = 93585: Friction factor (f) = 0.005

Fig. 10.2.4 'SI based' Moody chart (abridged)

From the European D'Arcy equation (Equation 10.2.1):

From the USA / AUS Moody chart (Figure 10.2.5),

Where: ks/D = 0.0003 Re = 93 585 Friction factor (f) = 0.02

Fig. 10.2.5 'Imperial based' Moody chart (abridged)

From the USA / AUS D'Arcy equation (Equation 10.2.2):

The same friction head loss is obtained by using the different friction factors and relevant D'Arcy equations.

In practice whether for water pipes or steam pipes, a balance is drawn between pipe size and pressure loss.

Oversized pipework means:

- Pipes, valves, fittings, etc. will be more expensive than necessary.

- Higher installation costs will be incurred, including support work, insulation, etc.

- For steam pipes a greater volume of condensate will be formed due to the greater heat loss. This, in turn, means that either:

- More steam trapping is required, or

- Wet steam is delivered to the point of use.

In a particular example:

- The cost of installing 80 mm steam pipework was found to be 44% higher than the cost of 50 mm pipework, which would have had adequate capacity.

- The heat lost by the insulated pipework was some 21% higher from the 80 mm pipeline than it would have been from the 50 mm pipework. Any non-insulated parts of the 80 mm pipe would lose 50% more heat than the 50 mm pipe, due to the extra heat transfer surface area.

Undersized pipework means:

- A lower pressure may only be available at the point of use. This may hinder equipment performance due to only lower pressure steam being available.

- There is a risk of steam starvation.

- There is a greater risk of erosion, waterhammer and noise due to the inherent increase in steam velocity.

As previously mentioned, the friction factor (f) can be difficult to determine, and the calculation itself is time consuming especially for turbulent steam flow. As a result, there are numerous graphs, tables and slide rules available for relating steam pipe sizes to flowrates and pressure drops.

One pressure drop sizing method, which has stood the test of time, is the 'pressure factor' method. A table of pressure factor values is used in Equation 10.2.2 to determine the pressure drop for a particular installation.

Equation 10.2.8

Where:

F = Pressure factor

P1 = Factor at inlet pressure

P2 = Factor at a distance of L metres

L = Equivalent length of pipe (m)

Example 10.2.2

Consider the system shown in Figure 10.2.6, and determine the pipe size required from the boiler to the unit heater branch line. Unit heater steam load = 270 kg/h.

Fig. 10.2.6 System used to illustrate Example 10.2.2

Although the unit heater only requires 270 kg/h, the boiler has to supply more than this due to heat losses from the pipe.

The allowance for pipe fittings

The length of travel from the boiler to the unit heater is known, but an allowance must be included for the additional frictional resistance of the fittings. This is generally expressed in terms of 'equivalent pipe length'. If the size of the pipe is known, the resistance of the fittings can be calculated. As the pipe size is not yet known in this example, an addition to the equivalent length can be used based on experience.

One pressure drop sizing method, which has stood the test of time, is the 'pressure factor' method. A table of pressure factor values is used in Equation 10.2.2 to determine the pressure drop for a particular installation.

Equation 10.2.8

Where:

F = Pressure factor

P1 = Factor at inlet pressure

P2 = Factor at a distance of L metres

L = Equivalent length of pipe (m)

Example 10.2.2

Consider the system shown in Figure 10.2.6, and determine the pipe size required from the boiler to the unit heater branch line. Unit heater steam load = 270 kg/h.

Fig. 10.2.6 System used to illustrate Example 10.2.2

Although the unit heater only requires 270 kg/h, the boiler has to supply more than this due to heat losses from the pipe.

The allowance for pipe fittings

The length of travel from the boiler to the unit heater is known, but an allowance must be included for the additional frictional resistance of the fittings. This is generally expressed in terms of 'equivalent pipe length'. If the size of the pipe is known, the resistance of the fittings can be calculated. As the pipe size is not yet known in this example, an addition to the equivalent length can be used based on experience.

- If the pipe is less than 50 metres long, add an allowance for fittings of 5%.

- If the pipe is over 100 metres long and is a fairly straight run with few fittings, an allowance for fittings of 10% would be made.

- A similar pipe length, but with more fittings, would increase the allowance towards 20%.

In this instance, revised length = 150 m + 10% = 165 m

The allowance for the heat losses from the pipe

The unit heater requires 270 kg/h of steam; therefore the pipe must carry this quantity plus the quantity of steam condensed by heat losses from the main. As the size of the main is yet to be determined, the true calculations cannot be made, but, assuming that the main is insulated, it may be reasonable to add 3.5% of the steam load per 100 m of the revised length as heat losses.

In this instance, the additional allowance =

Revised boiler load = 270 kg/h + 5.8% = 286 kg/h

From Table 10.2.2 (an extract from the complete pressure factor table, Table 10.2.5, which can be found in the Appendix at the end of this Tutorial) 'F' can be determined by finding the pressure factors P1 and P2, and substituting them into Equation 10.2.8.

Table 10.2.2 Extract from pressure factor table (Table 10.2.5)

From the pressure factor table (see Table 10.2.2):

P1 (7.0 bar g) = 56.38

P2 (6.6 bar g) = 51.05

Substituting these pressure factors (P1 and P2) into Equation 10.2.8 will determine the value for 'F':

Equation 10.2.8.

Equation 10.2.8.

Following down the left-hand column of the pipeline capacity and pressure drop factors table (Table 10.2.6 - Extract shown in Table 10.2.3); the nearest two readings around the requirement of 0.032 are 0.030 and 0.040. The next lower factor is always selected; in this case, 0.030.

Table 10.2.3 Extract from pipeline capacity and pressure factor table (Table 10.2.6)

Although values can be interpolated, the table does not conform exactly to a straight-line graph, so interpolation cannot be absolutely correct. Also, it is bad practice to size any pipe up to the limit of its capacity, and it is important to have some leeway to allow for the inevitable future changes in design.

From factor 0.030, by following the row of figures to the right it will be seen that:

The allowance for the heat losses from the pipe

The unit heater requires 270 kg/h of steam; therefore the pipe must carry this quantity plus the quantity of steam condensed by heat losses from the main. As the size of the main is yet to be determined, the true calculations cannot be made, but, assuming that the main is insulated, it may be reasonable to add 3.5% of the steam load per 100 m of the revised length as heat losses.

In this instance, the additional allowance =

Revised boiler load = 270 kg/h + 5.8% = 286 kg/h

From Table 10.2.2 (an extract from the complete pressure factor table, Table 10.2.5, which can be found in the Appendix at the end of this Tutorial) 'F' can be determined by finding the pressure factors P1 and P2, and substituting them into Equation 10.2.8.

Table 10.2.2 Extract from pressure factor table (Table 10.2.5)

From the pressure factor table (see Table 10.2.2):

P1 (7.0 bar g) = 56.38

P2 (6.6 bar g) = 51.05

Substituting these pressure factors (P1 and P2) into Equation 10.2.8 will determine the value for 'F':

Equation 10.2.8.

Equation 10.2.8.

Following down the left-hand column of the pipeline capacity and pressure drop factors table (Table 10.2.6 - Extract shown in Table 10.2.3); the nearest two readings around the requirement of 0.032 are 0.030 and 0.040. The next lower factor is always selected; in this case, 0.030.

Table 10.2.3 Extract from pipeline capacity and pressure factor table (Table 10.2.6)

Although values can be interpolated, the table does not conform exactly to a straight-line graph, so interpolation cannot be absolutely correct. Also, it is bad practice to size any pipe up to the limit of its capacity, and it is important to have some leeway to allow for the inevitable future changes in design.

From factor 0.030, by following the row of figures to the right it will be seen that:

- A 40 mm pipe will carry 229.9 kg/h.

- A 50 mm pipe will carry 501.1 kg/h.

Since the application requires 286 kg/h, the 50 mm pipe would be selected.

Having sized the pipe using the pressure drop method, the velocity can be checked if required.

Where:

Viewed in isolation, this velocity may seem low in comparison with maximum permitted velocities. However, this steam main has been sized to limit pressure drop, and the next smaller pipe size would have given a velocity of over 47 m/s, and a final pressure less than the requirement of 6.6 bar g, which is unacceptable.

As can be seen, this procedure is fairly complex and can be simplified by using the nomogram shown in Figure 10.2.9 (in the Appendix of this Tutorial). The method of use is explained in Example 10.2.3.

Example 10.2.3

Using the data from Example 10.2.2, determine the pressure drop using the nomogram shown in Figure 10.2.7.

Inlet pressure = 7 bar g

Steam flowrate = 286 kg/h

Minimum allowable P2 = 6.6 bar g

Method

Having sized the pipe using the pressure drop method, the velocity can be checked if required.

Where:

Viewed in isolation, this velocity may seem low in comparison with maximum permitted velocities. However, this steam main has been sized to limit pressure drop, and the next smaller pipe size would have given a velocity of over 47 m/s, and a final pressure less than the requirement of 6.6 bar g, which is unacceptable.

As can be seen, this procedure is fairly complex and can be simplified by using the nomogram shown in Figure 10.2.9 (in the Appendix of this Tutorial). The method of use is explained in Example 10.2.3.

Example 10.2.3

Using the data from Example 10.2.2, determine the pressure drop using the nomogram shown in Figure 10.2.7.

Inlet pressure = 7 bar g

Steam flowrate = 286 kg/h

Minimum allowable P2 = 6.6 bar g

Method

- Select the point on the saturated steam line at 7 bar g, and mark Point A.

- From point A, draw a horizontal line to the steam flowrate of 286 kg/h, and mark Point B.

- From point B, draw a vertical line towards the top of the nomogram (Point C).

- Draw a horizontal line from 0.24 bar/100 m on the pressure loss scale (Line DE).

- The point at which lines DE and BC cross will indicate the pipe size required. In this case, a 40 mm pipe is too small, and a 50 mm pipe would be used.

Fig. 10.2.7 Steam pipeline sizing chart - Pressure drop

Sizing pipes on velocity

From the knowledge gained at the beginning of this Tutorial, and particularly the notes regarding the D'Arcy equation (Equation 10.2.1), it is acknowledged that velocity is an important factor in sizing pipes. It follows then, that if a reasonable velocity could be used for a particular fluid flowing through pipes, then velocity could be used as a practical sizing factor. As a general rule, a velocity of 25 to 40 m/s is used when saturated steam is the medium.

40 m/s should be considered an extreme limit, as above this, noise and erosion will take place particularly if the steam is wet.

Even these velocities can be high in terms of their effect on pressure drop. In longer supply lines, it is often necessary to restrict velocities to 15 m/s to avoid high pressure drops. It is recommended that pipelines over 50 m long are always checked for pressure drop, no matter what the velocity.

By using Table 10.2.4 as a guide, it is possible to select pipe sizes from known data; steam pressure, velocity and flowrate.

Table 10.2.4 Saturated steam pipeline capacities in kg/h for different velocities (Schedule 40 pipe)

Alternatively the pipe size can be calculated arithmetically. The following information is required, and the procedure used for the calculation is outlined below.

Information required to calculate the required pipe size:

u = Flow velocity (m/s)

vg = Specific volume (m3/kg)

s = Mass flowrate (kg/s)

s = Mass flowrate (kg/s) = Volumetric flowrate (m3/s) = ms x vg

= Volumetric flowrate (m3/s) = ms x vgFrom this information, the cross sectional area (A) of the pipe can be calculated:

Rearranging the formula to give the diameter of the pipe (D) in metres:

Example 10.2.4

A process requires 5 000 kg/h of dry saturated steam at 7 bar g. For the flow velocity not to exceed 25 m/s, determine the pipe size.

Where

Therefore, using:

Since the steam velocity must not exceed 25 m/s, the pipe size must be at least 130 mm; the nearest commercially available size, 150 mm, would be selected.

Again, a nomogram has been created to simplify this process, see Figure 10.2.6.

Example 10.2.5

Using the information from Example 10.2.4, use Figure 10.2.6 to determine the minimum acceptable pipe size

Inlet pressure=7 bar gSteam flowrate=5000 kg/hMaximum velocity=25 m/s

Method:

- Draw a horizontal line from the saturation temperature line at 7 bar g (Point A) on the pressure scale to the steam mass flowrate of 5 000 kg/h (Point B).

- From point B, draw a vertical line to the steam velocity of 25 m/s (Point C). From point C, draw a horizontal line across the pipe diameter scale (Point D).

- A pipe with a bore of 130 mm is required; the nearest commercially available size, 150 mm, would be selected.

Fig. 10.2.8 Steam pipeline sizing chart - Velocity

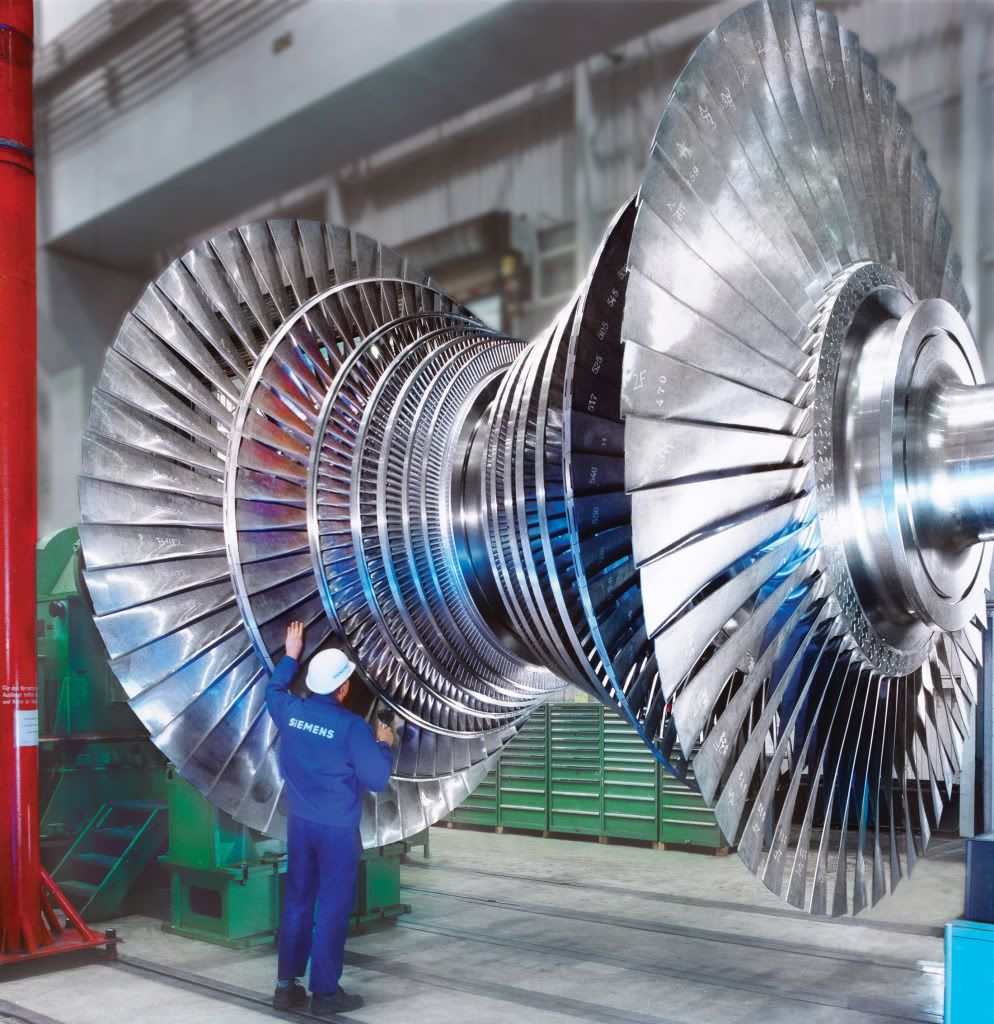

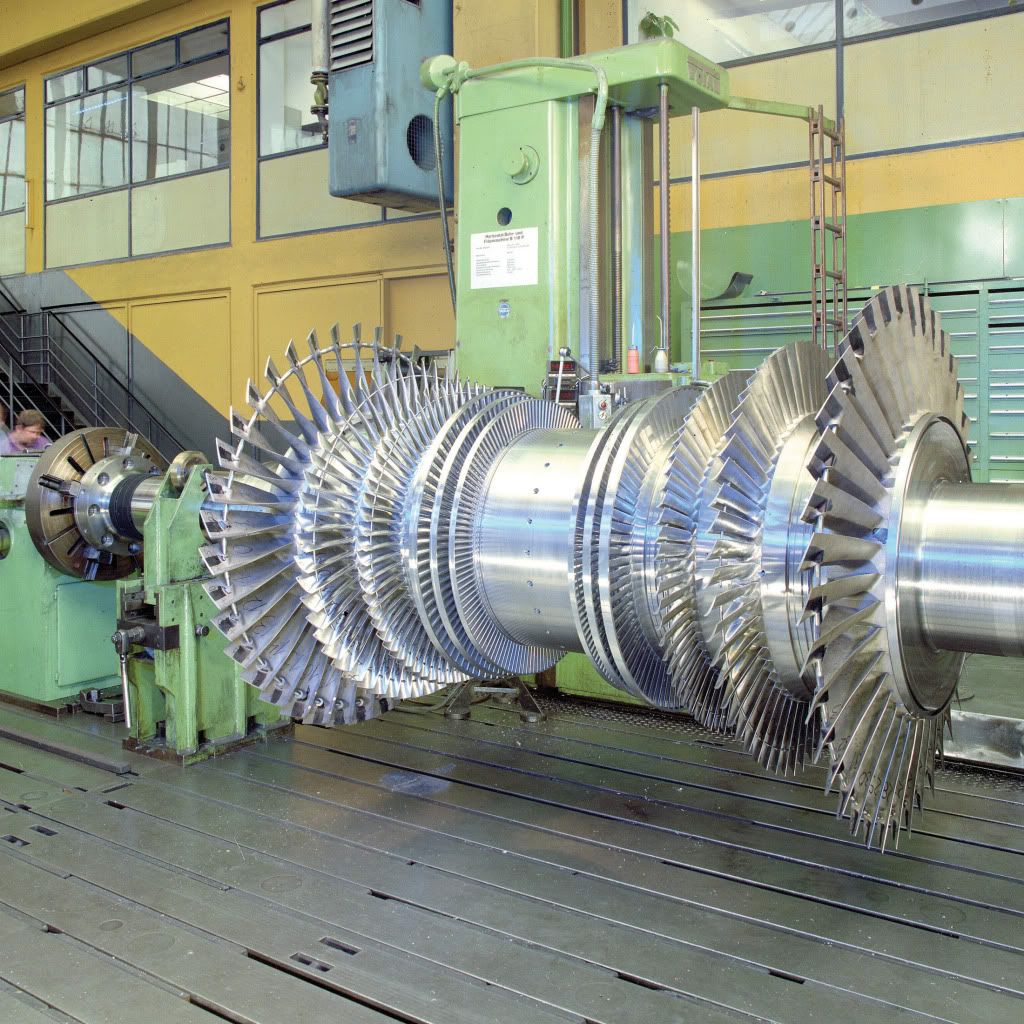

Sizing pipes for superheated steam duty

Superheated steam can be considered as a dry gas and therefore carries no moisture. Consequently there is no chance of pipe erosion due to suspended water droplets, and steam velocities can be as high as 50 to 70 m/s if the pressure drop permits this. The nomograms in Figures 10.2.5 and 10.2.6 can also be used for superheated steam applications.

Example 10.2.6

Utilising the waste heat from a process, a boiler/superheater generates 30 t/h of superheated steam at 50 bar g and 450°C for export to a neighbouring power station. If the velocity is not to exceed 50 m/s, determine:

- The pipe size based on velocity (use Figure 10.2.8).

- The pressure drop if the pipe length, including allowances, is 200 m (use Figure 10.2.9).

Part 1

- Using Figure 10.2.8, draw a vertical line from 450°C on the temperature axis until it intersects the 50 bar line (Point A).

- From point A, project a horizontal line to the left until it intersects the steam 'mass flowrate' scale of 30 000 kg/h (30 t/h) (Point B).

- From point B, project a line vertically upwards until it intersects 50 m/s on the 'steam velocity' scale (Point C).

- From Point C, project a horizontal line to the right until it intersects the 'inside pipe diameter' scale.

The 'inside pipe diameter' scale recommends a pipe with an inside diameter of about 120 mm. From Table 10.2.1 and assuming that the pipe will be Schedule 80 pipe, the nearest size would be 150 mm, which has a bore of 146.4 mm.

Part 2

Part 2

- Using Figure 10.2.7, draw a vertical line from 450°C on the temperature axis until it intersects the 50 bar line (Point A).

- From point A, project a horizontal line to the right until it intersects the 'steam mass flowrate' scale of 30 000 kg/h (30 t/h) (Point B).

- From point B, project a line vertically upwards until it intersects the 'inside pipe diameter' scale of (approximately) 146 mm (Point C).

- From Point C, project a horizontal line to the left until it intersects the 'pressure loss bar/100 m' scale (Point D).

The 'pressure loss bar/100 m' scale reads about 0.9 bar/100 m. The pipe length in the example is 200 m, so the pressure drop is:

This pressure drop must be acceptable at the process plant.

Using formulae to establish steam flowrate on pressure drop

Empirical formulae exist for those who prefer to use them. Equations 10.2.9 and 10.2.10 are shown below. These have been tried and tested over many years, and which appear to give results close to the pressure factor method. The advantage of using these formulae is that they can be programmed into a scientific calculator, or a spreadsheet, and consequently used without the need to look up tables and charts. Equation 10.2.10 requires the specific volume of steam to be known, which means it is necessary to look up this value from a steam table. Also, Equation 10.2.10 should be restricted to a maximum pipe length of 200 metres.

Pressure drop formula 1

Equation 10.2.9

Where:

P1=Upsteam pressure (bar a)P2=Downstream pressure (bar a)L=Length of pipe (m) s=Mass flowrate (kg/h)D=Pipe diameter (mm)

s=Mass flowrate (kg/h)D=Pipe diameter (mm)

Pressure drop formula 2 (Maximum pipe length: 200 metres)

Equation 10.2.10

Equation 10.2.10

Where:

DP=Pressure drop (bar)L=Length of pipevg=Specific volume of steam (m3/kg) =Mass flowrate(kg/h)D=Pipe diameter (mm)

=Mass flowrate(kg/h)D=Pipe diameter (mm)

Summary

This pressure drop must be acceptable at the process plant.

Using formulae to establish steam flowrate on pressure drop

Empirical formulae exist for those who prefer to use them. Equations 10.2.9 and 10.2.10 are shown below. These have been tried and tested over many years, and which appear to give results close to the pressure factor method. The advantage of using these formulae is that they can be programmed into a scientific calculator, or a spreadsheet, and consequently used without the need to look up tables and charts. Equation 10.2.10 requires the specific volume of steam to be known, which means it is necessary to look up this value from a steam table. Also, Equation 10.2.10 should be restricted to a maximum pipe length of 200 metres.

Pressure drop formula 1

Equation 10.2.9

Where:

P1=Upsteam pressure (bar a)P2=Downstream pressure (bar a)L=Length of pipe (m)

s=Mass flowrate (kg/h)D=Pipe diameter (mm)

s=Mass flowrate (kg/h)D=Pipe diameter (mm)Pressure drop formula 2 (Maximum pipe length: 200 metres)

Equation 10.2.10

Equation 10.2.10Where:

DP=Pressure drop (bar)L=Length of pipevg=Specific volume of steam (m3/kg)

=Mass flowrate(kg/h)D=Pipe diameter (mm)

=Mass flowrate(kg/h)D=Pipe diameter (mm)- The selection of piping material and the wall thickness required for a particular installation is stipulated in standards such as EN 45510 and ASME 31.1.

- Selecting the appropriate pipe size (nominal bore) for a particular application is based on accurately identifying pressure and flowrate. The pipe size may be selected on the basis of:

- Velocity (usually pipes less than 50 m in length).

- Pressure drop (as a general rule, the pressure drop should not normally exceed 0.1 bar/50 m.

Table 10.2.5 Pressure drop factor (F) table

Table 10.2.6 Pipeline capacity and pressure factor table

Fig 10.2.9 Steam pipeline sizing chart - Pressure drop

Fig 10.2.10 Steam pipeline sizing chart - Velocity

الاشتراك في:

التعليقات (Atom)